Design first, don’t pay later

Renewable energy systems, particularly heat pumps, are complex by their nature and need to be designed carefully to ensure they work at an optimal efficiency. Although most manufacturers provide basic designs to get their equipment working, isoenergy will exceed these basic designs and ensure the equipment is designed to work optimally with the overall system.

By employing our own design team we are able to bring the full force of our installation experience to bear on projects and will always tailor the solution to meet the particular needs of your site. The main benefit of our custom designs can be seen in the system’s efficiency. Our systems consistently run at the highest efficiency. So the little extra investment in careful design will be reflected in savings for years to come.

A common point of reference

A common point of reference

There are of course other advantages to each project having a clear set of designs such as allowing us and other contractors to manage the work on site. This way the trenches are dug in the right place, boreholes are drilled as needed, and the contractor doing the house plumbing knows how their work fits with ours. This helps you manage costs as all stake holders in the project will have a common point of reference.

Attention to detail

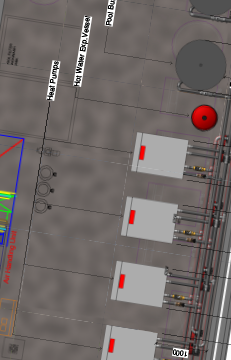

Once the practical work is completed the designs are updated to provide drawings of record for long term maintenance of the system. Depending on the type of technology installed drawings will be produced that show the ground works layout, a plan of the plant room, a 3D view of the plant room, a plumbing and instrumentation schematic diagram and any electrical schematics required.

Our design team is also able to specify and design custom control systems allowing greater control and integration with building management systems.

The latest tools

The team uses a variety of design tools such as AutoCAD, Revit and SEE Electrical Design software, coupled with a number of custom tools designed to calculate the fluid dynamics and key parameters of the system such as pool heating loads. These custom tools have been developed over the years we have been installing renewable energy systems and are unique to our designs.

It is this attention to detail that makes the difference and leads to the excellent performance seen in isoenergy systems.