In our experience, plant room control systems come in many different shapes and sizes all custom designed for each application. Sometimes this is a simple timer and other times a whole building management system. However, the vast majority of systems need a solution that is somewhere between the two.

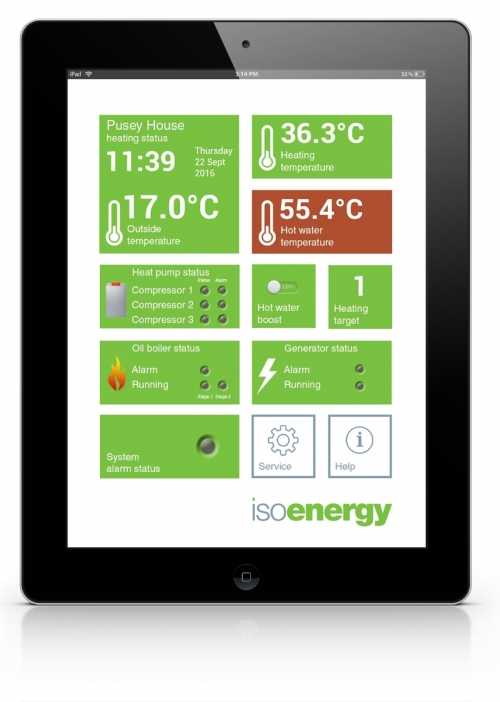

Isoenergy has designed a built a new control system for its most recent installation at Pusey House, Oxfordshire. The site has various heating targets and heat now supplied by two different ground source heat pumps with an oil boiler in place for backup should it ever be required. Although each Viessmann heat pump comes with an integrated controller, the functionality and changeable settings they present to a client can be too much to take in during training. Therefore, we took the decision to distil all the various control options down to just a couple of functions. The system also has the benefit of allowing for remote diagnostics of the entire plantroom with all its ancillary equipment such as circulation pumps, backup generator and mixing valves.

Keeping you informed

With any complex system, having the right information in one place is key to ensuring its operation runs smoothly. The isoenergy control system shows current data such as the outside air temperature, the heating buffer tank temperature and the current hot water temperature. The system also indicates when the heat pumps are running and if there are any issues.

Simplified controls

Rather than having to learn a whole host of different control parameters for each part of the system, for the client at Pusey house we have distilled all the controls down to two features. Hot water boost, which means the heat pumps and oil boiler if required, will work to keep the water at a slightly higher temperature than normal to deal with times of very high hot water demand. The other feature is a simple adjustment to the heat curve. This means the client can turn the heating up or down a little should there be an unexpectedly cold snap or unseasonal warm period.

System status reporting

As the new control system is accessed from a web-enabled device, it is possible for isoenergy staff to access it remotely from our office in Surrey. Each element of the system is able to report any alarms or faults that come up in real time. This helps us offer a first class support and maintenance programme for the client. The system also enables our service engineers to test and activate each individual piece of equipment to help diagnose any issues.

As each control system is customised for each plantroom it is installed into, features and functions can also be customised to your requirements. For more information or to discuss how the new isoenergy control system could work for you, please contact us on 01293 821 345 or email This email address is being protected from spambots. You need JavaScript enabled to view it..